Water Base or Plastisol?

When it comes to screen printing, one of the main decisions that businesses and organizations have to make is whether to use water-based or plastisol inks. While both types of inks have their own advantages and disadvantages, it’s important to understand the impact that each type of ink has on the environment, and the way they are cleaned up.

Clean-up and Impact

Are you looking for an environmentally responsible way to create custom designs with screen printing? With so many ink options, it can be tough to choose the right one. That’s why in this article, we’re diving deep into the pros and cons of two of the most popular types of screen printing inks: water-based and plastisol inks.

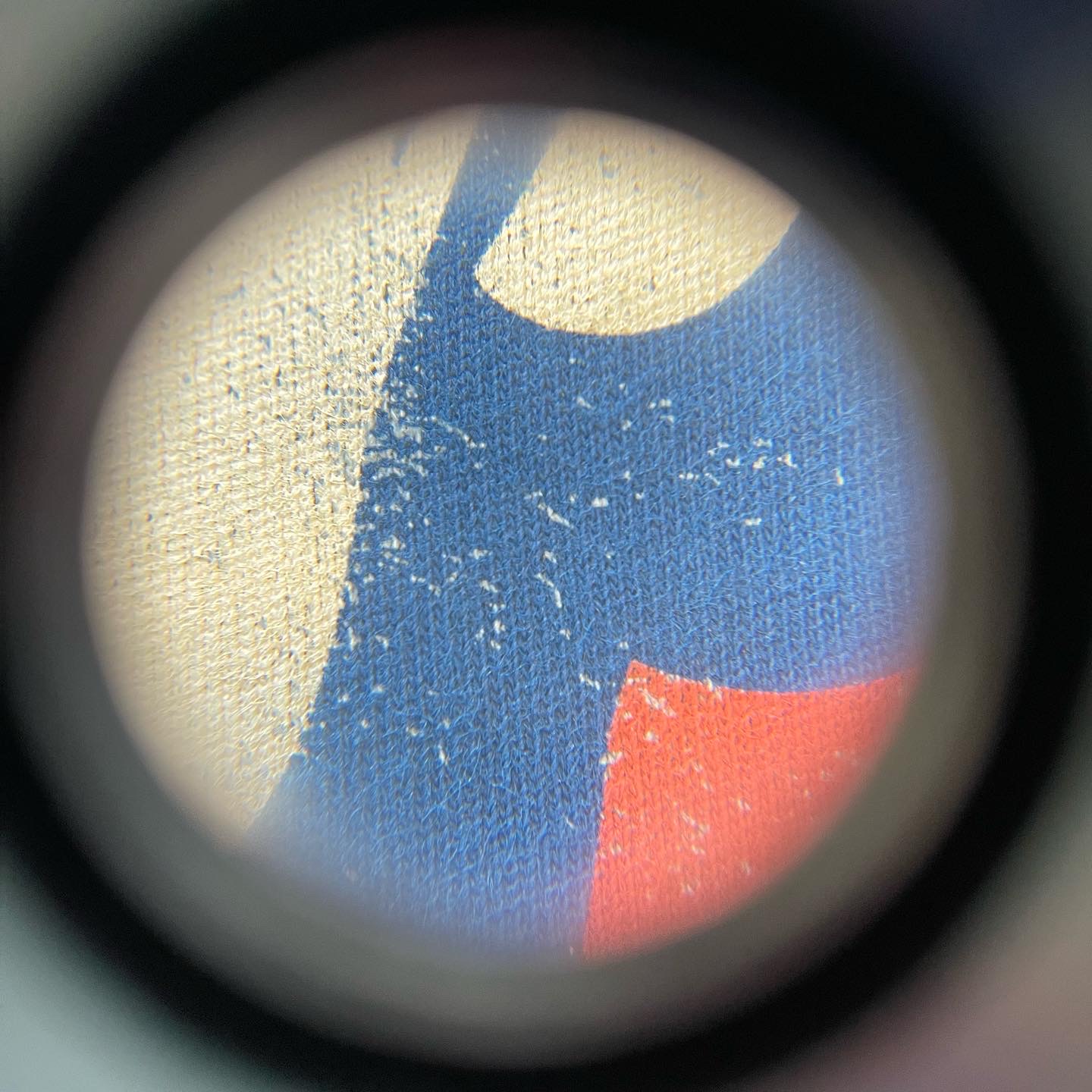

First, let’s talk about water-based inks. These inks are made with a blend of water, pigments, and a binder, making them biodegradable and able to break down naturally in the environment. In contrast, plastisol inks contain PVC and plasticizers and can take hundreds of years to degrade.

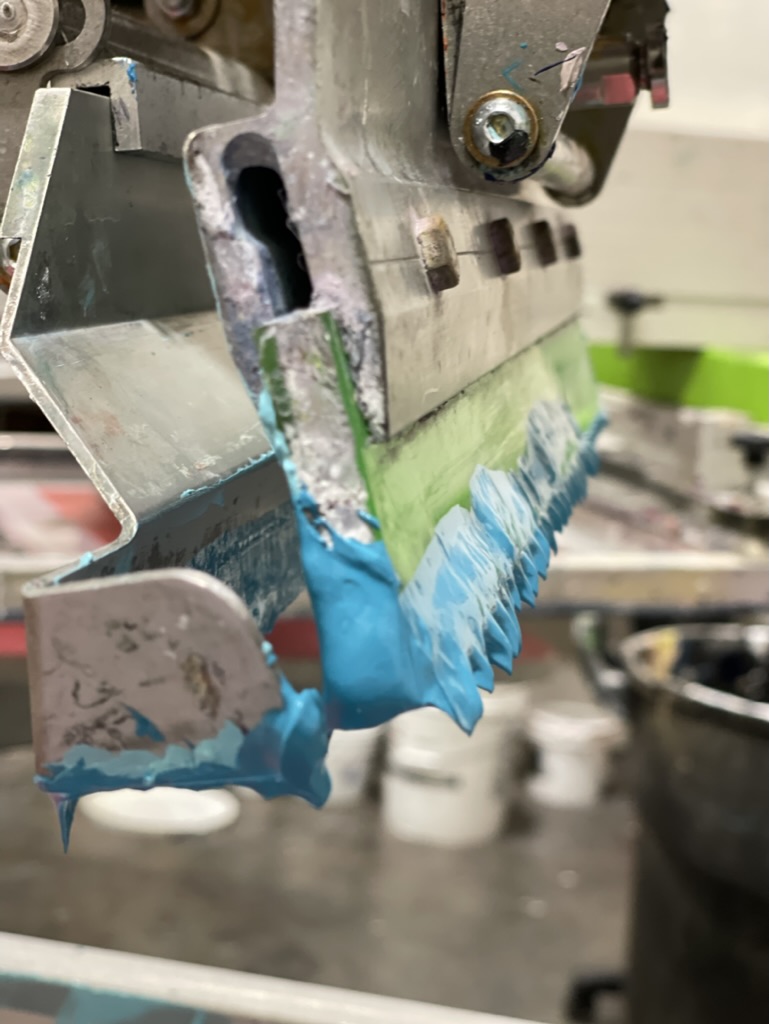

When it comes to clean up, water-based inks are the clear winner. They are water-soluble, so you can easily clean up any spills with just water and soap. Plastisol inks, however, are not water-soluble and require solvents such as mineral spirits or special screen printing ink cleaners for removal. These solvents can have a harmful impact on the environment if not disposed of correctly.

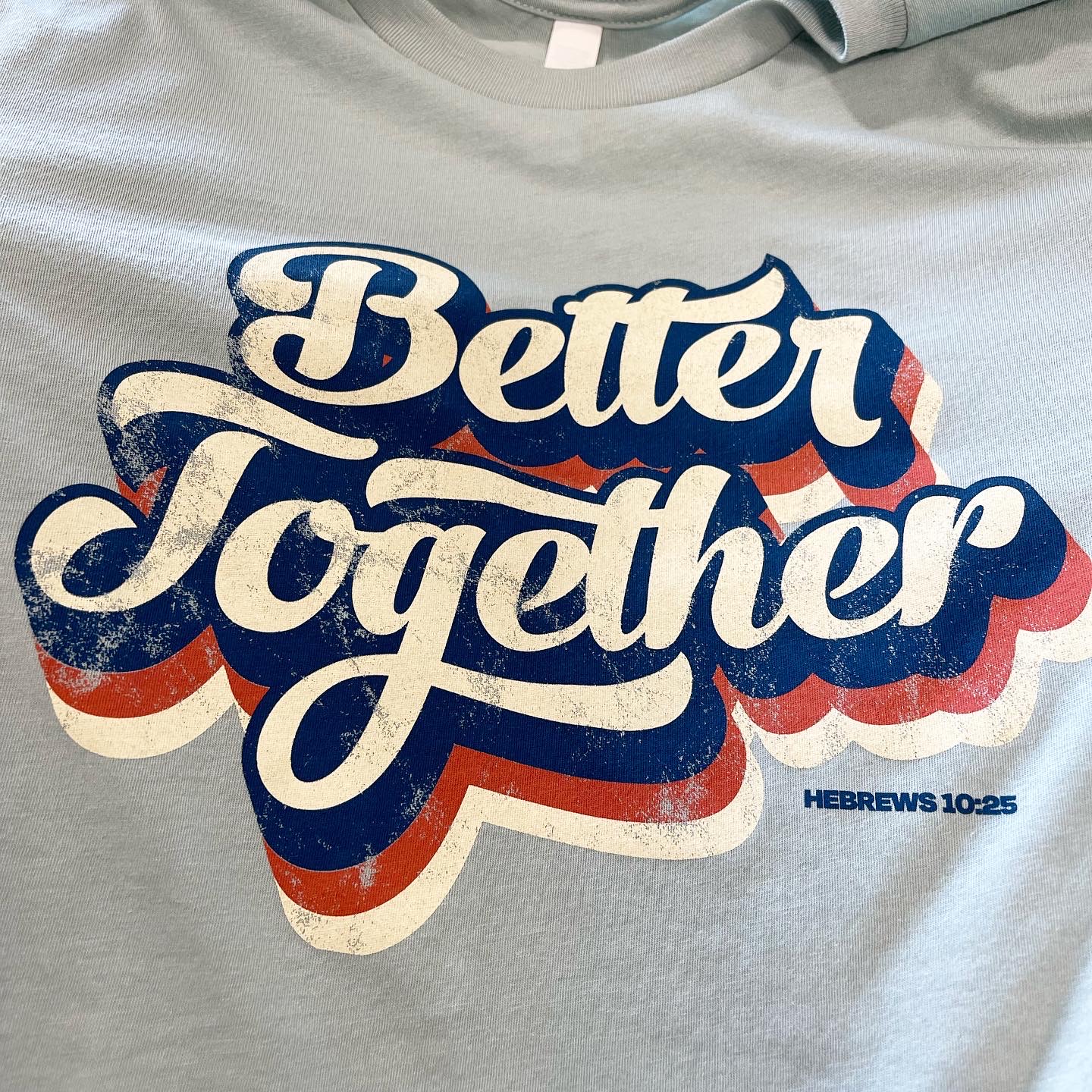

In addition to being easier to clean, water-based inks also have a softer feel and produce less odor, making for a more comfortable and pleasant working environment for employees. When it comes to air quality, water-based inks emit lower levels of Volatile Organic Compounds (VOCs), which have been linked to poor air quality. This makes water-based inks a safer and more eco-friendly option for both the environment and those working with them.

In conclusion, water-based inks are the way to go if you’re looking for an eco-friendly option for your screen printing needs. They are biodegradable, easy to clean, produce less odor, and have a lower impact on air quality. So, when choosing an ink for your screen printing projects, consider the impact on the environment and opt for a water-based ink.