Screen Printing Explained

Screen Printing is the act of pushing ink through a mesh screen. Silk screening has come a long way since it was created in the 1900s. Nowadays people push ink through a mesh screen using what we call a squeegee. Inks come in a few different forms and have many different uses, advantages and disadvantages. The industry’s leading type of textile printing ink is what we call plastisol. This screen printing ink has been around before silk screening was even invented (1838)! Water based ink made its debut in the 1900s but didn’t actually get popular until the 1970s. The Last textile ink used by screen printing is discharge ink. Discharge ran its course as being a hot fad and it still serves a great purpose today.

Plastisol Screen Printing

You can walk into just about any screen printing shop these days and most will be using plastisol ink. You may wonder what’s so significant or why? This t-shirt ink is extremely easy to print with. In most cases it cures easily. When using the appropriate screen mesh it’s easy to print wet on wet making production go quickly. Plastisol ink leaves the garment with a vibrant print. Plastisol sits on top of the garments fibers typically leaving you with a pretty thick print. Learn More >

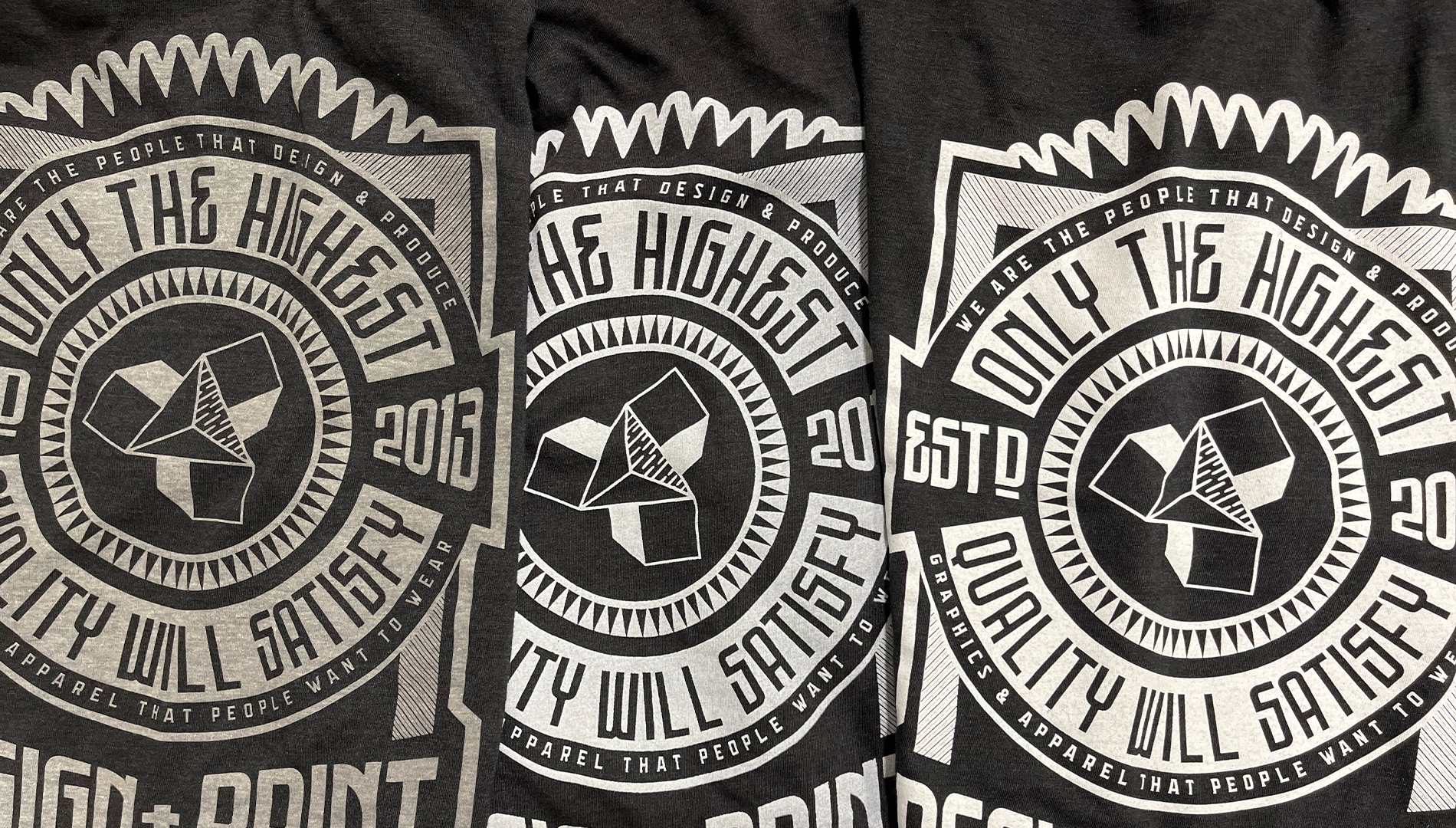

Opake Screen Printing is kind of an outcast and chooses not to print with this ink. Even though there are many benefits, this ink has become an environmental disaster. You need solvent degraders to break down the ink during clean up, shirts with this ink don’t biodegrade quickly in landfills. A lot of shops don’t filter these impurities out before they hit the drane.

Water Based Screen Printing

There’s a lot of irony behind the phrase “ history repeats itself” when it comes to water based ink. This silk screening ink was hot in the textile industry in the 80s. People really had to master their craft to print with this ink. Water base is not a set it and forget it kind of ink. With environments in low humidity the ink tends to dry out on the screen fairly quickly! Once plastisol came out it was far more enticing to print shops as they could leave jobs on press and come back later. Waterbase has its place and market though. This ink has been revised and reformulated to print with more ease and vibrancy. Although it can be a challenge to work with, the customer is left with a far more valuable print in my opinion. Like plastisol, Waterbase sits on top of the garment the difference being the print is more thin, durable, breathable and soft. Unlike plastisol screen printing ink, Waterbase cleans up very easily. We don’t need any nasty solvent sprays or ink degraders, simply water. We have found that water based ink pairs well with hemp t shirts and triblends. Hemp and water based ink generally fall in the same category as being more environmentally conscious. Tri blends pair nicely as it’s a softer shirt. I mean who doesn’t want a soft print on a soft shirt?

Discharge Screen Printing

Have you ever got a tshirt and went to go feel the print and it was almost as if it didn’t even exist? That’s discharge ink. Discharge is a water based ink with a formaldehyde additive. When you pair these two and push it through a mesh screen you’re left with the one of the softest prints you can get. The formaldehyde dyes the garment back to its original state allowing for the pigment of the silk screen ink to sit in the fibers of the t-shirt. Although you get a very soft print, discharge ink isn’t the most vibrant option. A lot of people choose to use discharge as an underbase so they can stack plastisol or water based ink over it. This technique gives the hoodies or t-shirts a soft print while achieving vibrancy.

Discharge screen printing can be very challenging as you have the production complexities as a water base but you also have to deal with the formaldehyde additive. If you’re looking for that vintage band tshirt look, discharge ink can be a great option. Unfortunately with the additives, this ink is not an environmentally friendly option. It can be an extremely hazardous option to the planet and the printer. Learn More >

What’s the best Screen Printing Method?

As you run through these different screen printing ink options wondering which is best for you, ask yourself what you’re trying to achieve! Do you want a breathable print while you swing a hammer or run that half marathon? Do you want that thick plastic print that could have saved Captain America? Or do you want to storm the halls like it’s 1977 in a Van Halen replica? At Opake we perfected our craft with water based ink and we live by it. We choose to be eco conscious.